Multitubo komposiittorud

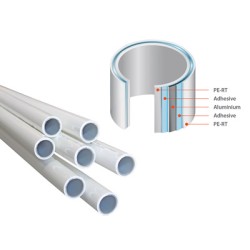

The pipe

The multi-layer pipe– the fundamental part for all of our connections

Multi-layer pipes – a compound of high-class-materials – are the most popular pipes in the sanitary- and heating-installations in the trend-setting market Europe. Practically all advantages of a modern material: fully balanced between it's highest operating performance and it's environmental compatibility due to an economical resource management

Highest material quality

With an experience of more that 25 years in producing overlapped welded multi-layer pipes MULTITUBO systems is holding a pipe which safety-resource isone of the highest worldwide.

Highest material safety

Selected raw materials and a long experience in production guarantee the top quality of a technical perfected product. The pipe offers a high load capacity at tmax 95°C and pmax 10 bar (at 70°C according to the DVGW-regulations) for the daily use.

Simple bendability

The standard diameters up to 25mm can be easily bent without any tools. The bending-springs provide exact roundings at narrow bending radii.

Advantages like metal-pipes

- absolutely oxygen tight because of the welded aluminium pipe

- form stable, no spring back forces

- low thermal length expansion

Advantages like plastic pipes

- no deposits because of the smooth inside wall

- no corrosion because of the high chemical resistance

- low weight

Subcategories

-

Metal-Press fitting

Metal-Press-Fitting

The Metal-Press-Fitting is the universal connection method for dim. 16 mm to 75 mm. Top safety and the widest range of articles for each installation.

Fitting design:

The pressing-sleeve is fixed to the tin-plated brass body (dim 16 to 32 mm) and protects the O-rings of being damaged.

Inspection windows in the pressing-sleeves enable an easy check of the correct insertion-depth of the pipe.

The pressing-sleeve has a double flange press-jaw guide that make a proper pressing easier even at poorly accessible positions.

After pressing the pipe is permanently fixed to the fitting body by the pressing-sleeve. So the pipe can still be turned and adjusted after the pressing-process.

The additional test safety enables to detect un-pressed connections during the pressure test (test pressure 10 bar) of dimensions 16 mm to 32 mm.

-

Composite pipe

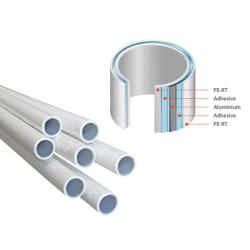

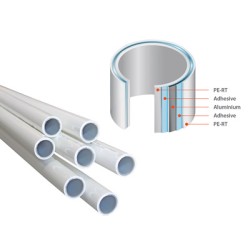

The pipe

The multi-layer pipe– the fundamental part for all of our connections

Multi-layer pipes – a compound of high-class-materials – are the most popular pipes in the sanitary- and heating-installations in the trend-setting market Europe. Practically all advantages of a modern material: fully balanced between it's highest operating performance and it's environmental compatibility due to an economical resource management

Highest material quality

With an experience of more that 25 years in producing overlapped welded multi-layer pipes MULTITUBO systems is holding a pipe which safety-resource isone of the highest worldwide.

Highest material safety

Selected raw materials and a long experience in production guarantee the top quality of a technical perfected product. The pipe offers a high load capacity at tmax 95°C and pmax 10 bar (at 70°C according to the DVGW-regulations) for the daily use.

Simple bendability

The standard diameters up to 25mm can be easily bent without any tools. The bending-springs provide exact roundings at narrow bending radii.

Advantages like metal-pipes

- absolutely oxygen tight because of the welded aluminium pipe

- form stable, no spring back forces

- low thermal length expansion

Advantages like plastic pipes

- no deposits because of the smooth inside wall

- no corrosion because of the high chemical resistance

- low weight